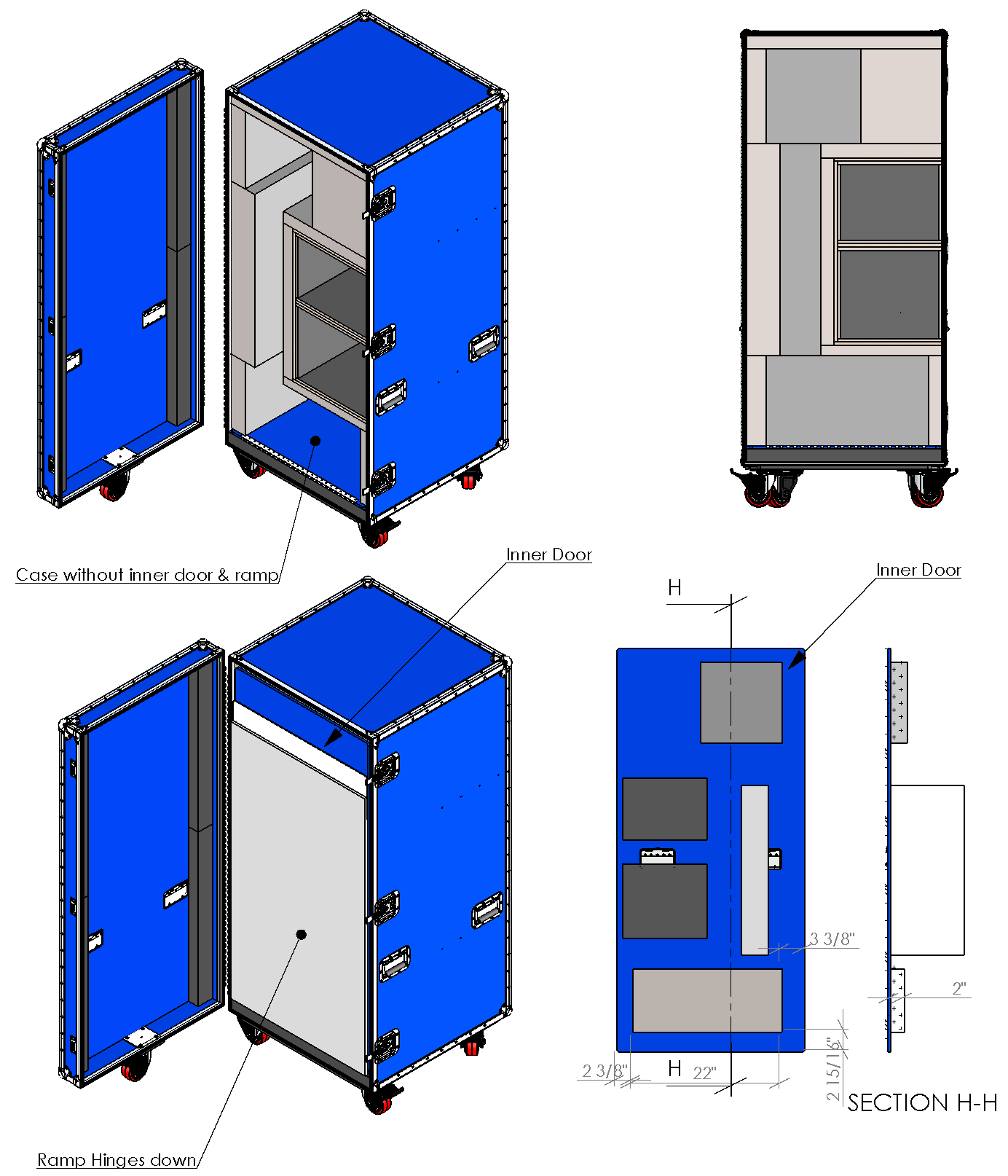

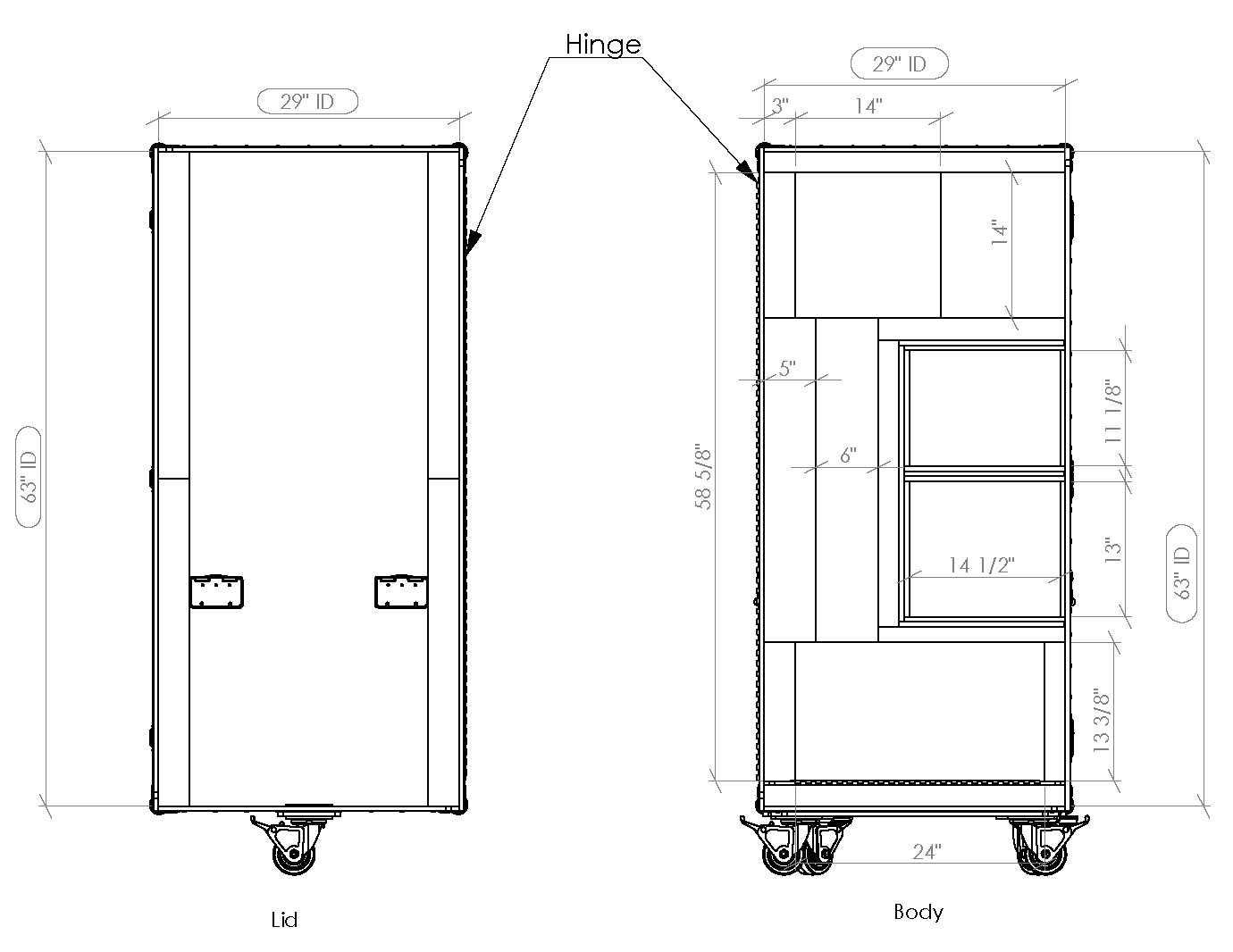

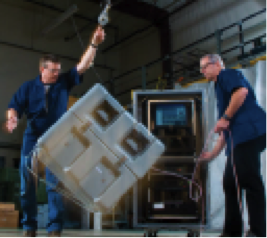

Custom cases are our specialty! We handle it all! Our staff will work with you to design a case to meet your exact requirements. We are experienced with jobs large and small, simple and complex. Contact us today!

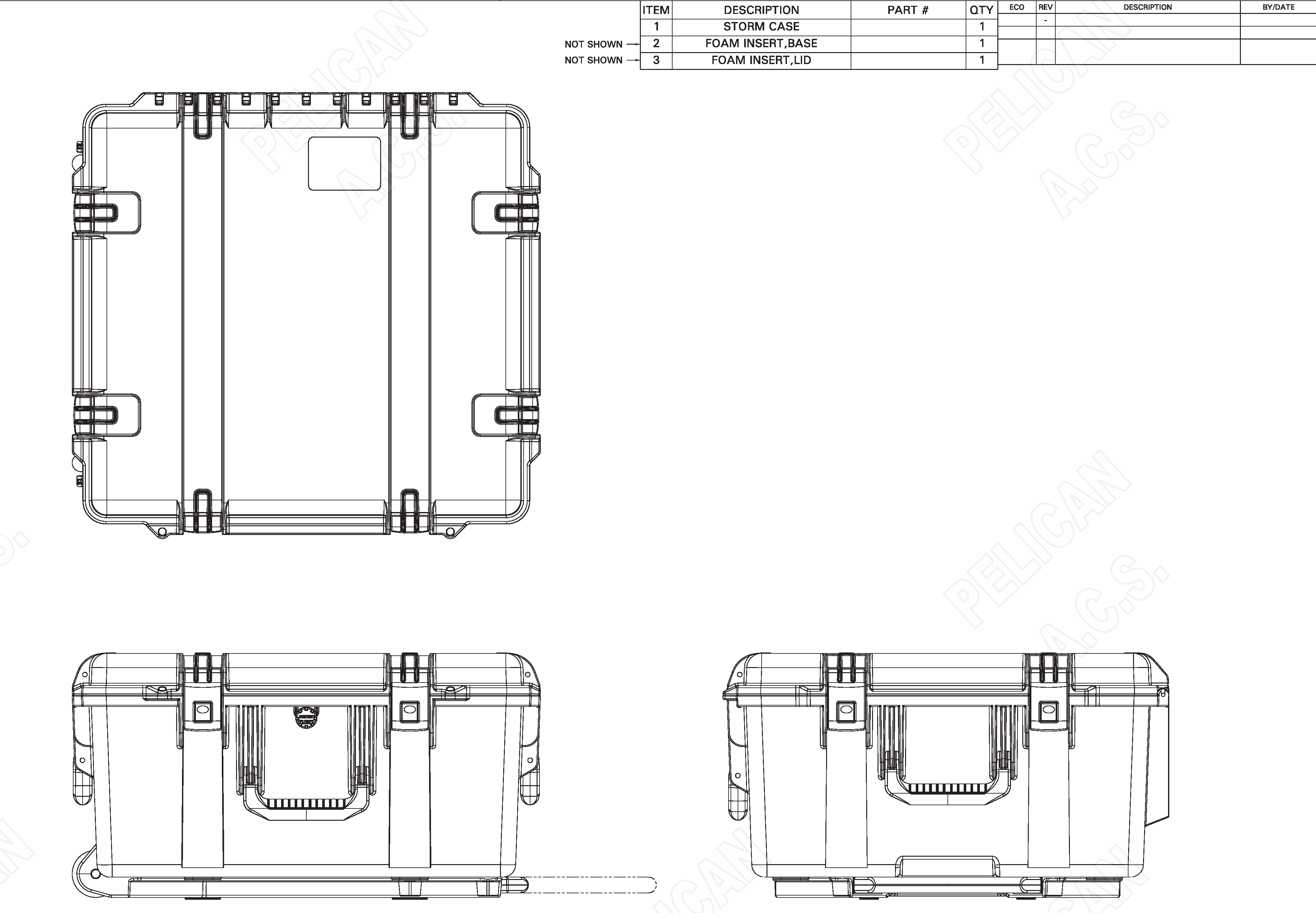

- Product Specifications

- Customer Performance Needs

- Product Interface and Access Point

- Stability, Impact and Drop Requirements

- Environmental and Field Conditions

- Vent and Pressure Requirements

- Mobility and Freight Compliance

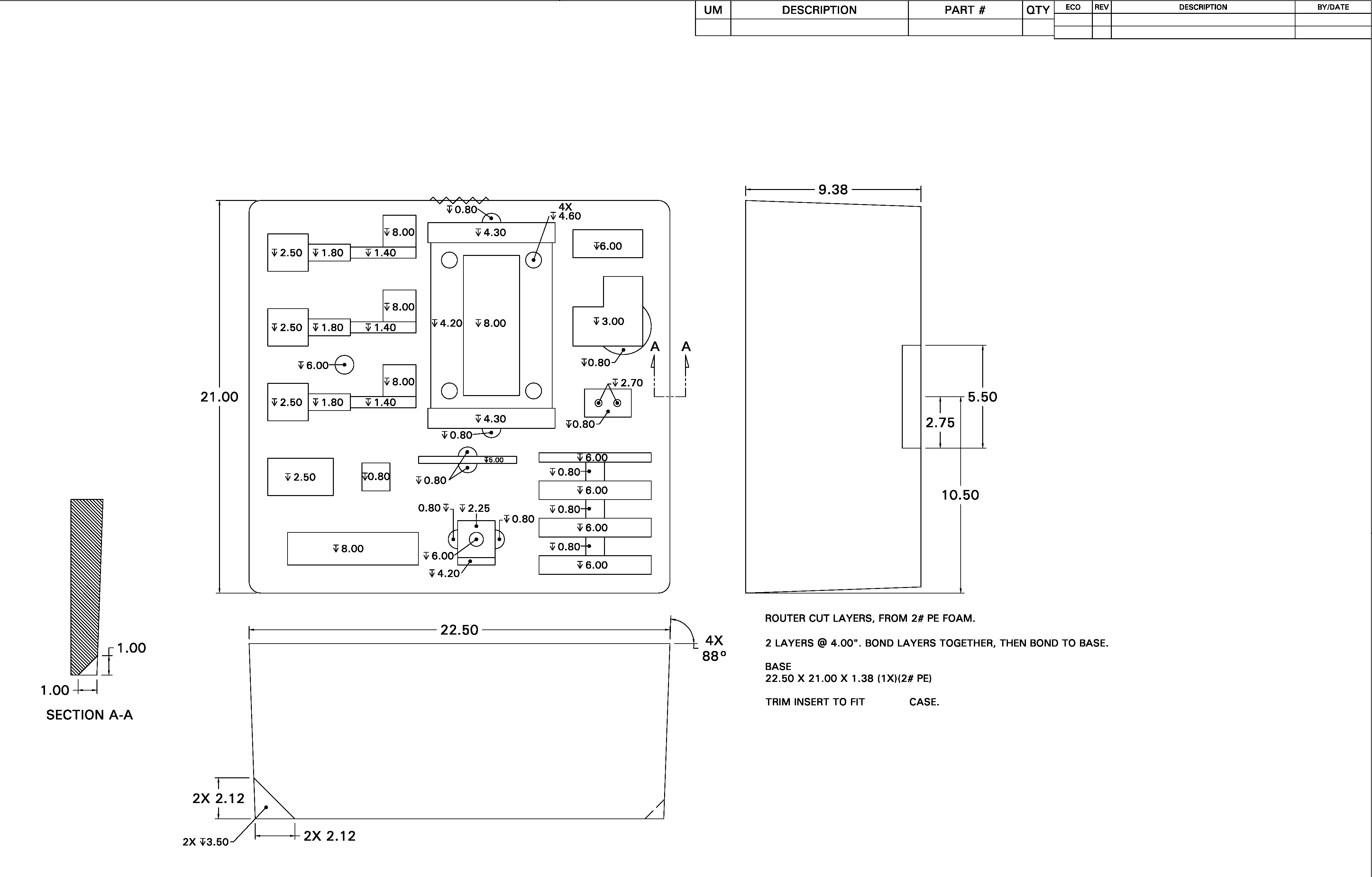

- CAD, 2D Layout and Solid Models

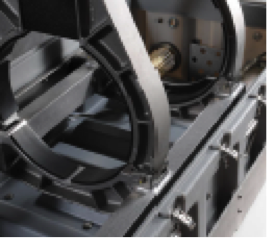

- G-Force Mapping and Applied Cushioning Curve » Tooling Design

- Equipment Support and Cradle Design

- Part Isolation and Sway Space Planning

- Usage and Operation Optimization

- Environmental Analysis

- Shock and Vibration Attenuation

- Submersion and Rain Resistance

- Shear Force Testing

- Dust Particulate Ingress

- G-Force at Specified Drop Heights

- Extreme Temperature Tolerances

- Mil-Spec Testing

- Warranted Parts and Accessories Engineered to Specifications

- Integration of Customer Parts and

- Accessories Per Functional Specifications

- Quality Control Testing and Inspection

- On Time Delivery

- Technical Support

Pro-Tech Case offers CUSTOM FOAM for all of your transporting, storage, shipping, protection and organizational needs. Our team has the knowledge, experience, and tools needed to cut foam for any size case, object, or project in general.

We use 2-D and 3-D scanning technology to accurately capture your projects exact dimensions, and then fabricate the required foam to the required dimensions. We offer a variety of different types of foams which allows us to provide you with a wide range of protection, including closed-cell foams, open-cell foams, and ESD foams, and style combination.